visit the manufacturer's website at geartronics.co.uk

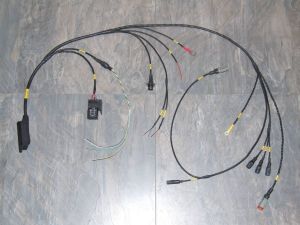

It's fair to say that a lot can be learned about the quality of a motorsport electronic product by examining the quality of the wiring harness that comes with it. That's why all Geartronics paddleshift looms exclusively use Raychem 'spec-55' wire and DR25 sleeving.

These materials are used at the highest levels of the sport, including F1 and LMP, because of their superior performance & reliability. All Geartronics looms are supplied with identification labels at every connection point.

Click pictures to enlarge

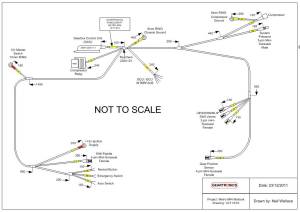

Most Geartronics paddleshift harnesses are designed and drawn using Visio. Customers will receive a copy of the drawing and also a pinout of the loom if required.

That way, if anything goes wrong, or the loom gets damaged, you're not working in the dark.

The connectors also play a big part in the reliability of the wiring installation. We only use sealed connectors in the construction of our looms, using the correct crimp tooling. Our highest specification looms are fitted with MIL-spec Deutsch Autosport connectors for ultimate reliability. Our 'professional' harnesses also include Raychem moulded joints that are fully sealed using 'system-25' adhesive.

If your budget doesn't permit the use of AS connectors then we can terminate looms using the more economical Deutsch 'DTM' or Sureseal connectors.

The loom construction still uses Raychem 55 wire and DR25 sleeving, but if we're working to a tighter budget then the moulded and glued joints of the 'professional'

loom are replaced with 'ATUM' adhesive lined heat-shrink to maintain reliability & asthetics. We never use braided sleeving or bullet/spade connectors in any of our looms.

Please note that we no not supply 'generic' looms and expect you to make it fit. All our paddleshift harnesses are bespoke, and are either built to customer supplied drawings or to our own drawings after measurements are taken on the car.